Pipe Beveling, Cutting, Facing Systems / Supplier And Exporter

Pipe beveling, cutting, and facing are common processes used in various industries, particularly in welding and piping operations. Pipe beveling, pipe cutting, and pipe facing tools are now much more accurate and efficient because of their in-depth specialization using the latest technology. These machines can handle

a range of pipe diameters, wall thicknesses, and materials since they come in different sizes and configurations. Technology advancements have also resulted in the creation of automated pipe

processing equipment that can complete several jobs, including beveling, cutting, and facing, in

a single operation, greatly increasing pipeline fabrication productivity and quality.

Pipe Beveling:

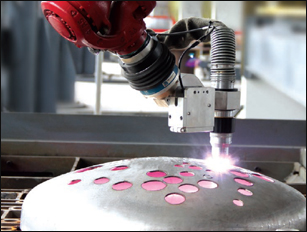

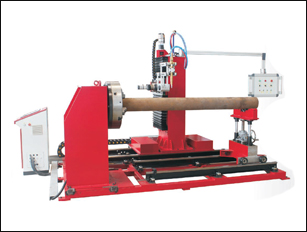

The technique of Beveling involves trimming a slope or angle off a pipe's edge. Usually, this is done to get the pipe ready for welding. Beveled edges increase the strength of the welded joint overall by facilitating greater weld penetration and smoothing the transition between the welded parts. This lowers the possibility of flaws. A variety of instruments,including hand grinders, beveling machines, and automated cutting systems, can be used for beveling.Pipe Cutting:

To get the appropriate length or to ready the pipe ends for welding, threading, or other connecting techniques, pipe cutting entails removing parts of the pipe. Pipes can be cut using a variety of tools, including bandsaws, abrasive cutting machines, and plasma cutting systems, as well as mechanical tools like hacksaws, pipe cutters, and reciprocating saws. The project requirements, pipe material, thickness, and diameter, among other criteria, influence the cutting process selection.Pipe Facing:

The process of machining or polishing a pipe's end face to make sure it is flawless, flat, and perpendicular to the pipe axis is known as Facing. In order to achieve correct alignment and fit-up during welding or joining processes, this is crucial. Lathes, facing machines, or portable facing equipment made especially for pipe applications are frequently used for pipe facing.These procedures are essential for guaranteeing the performance, integrity, and quality of pipe systems in a variety of settings, such as the industrial, petrochemical, oil and gas, and construction sectors. Pipe ends that have been properly prepared aid in effective and superior welding, producing sturdy and dependable connections that satisfy legal and industrial needs.